What is dry aging

THE SECRET TO A SUPERIOR STEAK

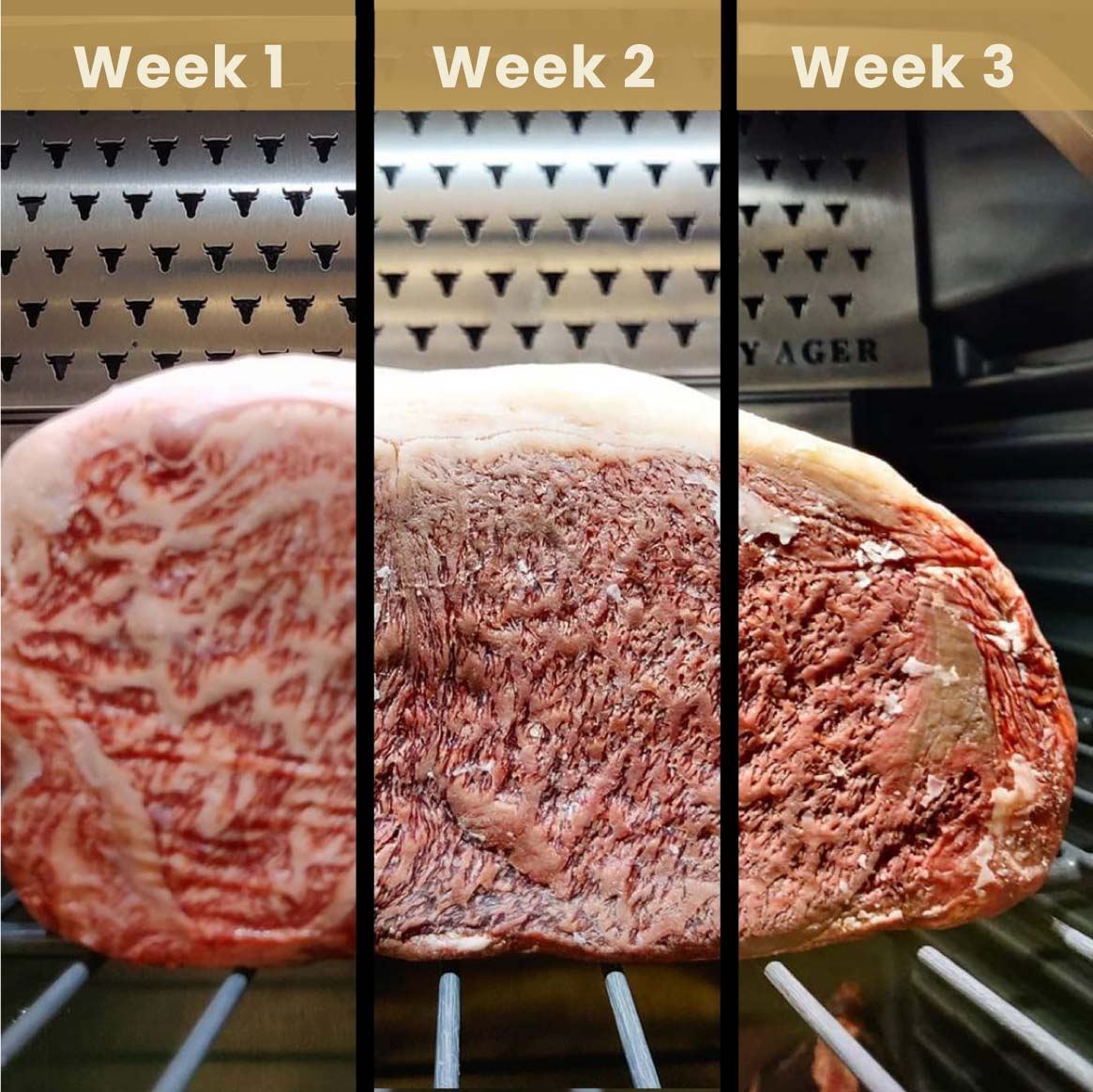

Storing and dry-aging meat is a proven method to maximise a product’s consistency and intensify its flavour. All fresh meat is aged at least a few days, but dry-aging extends this period to 4-6 weeks to achieve the perfect steak. With no extra expertise or effort required, and with just a little more time, your product (and business) can elevate to a higher standard than your competition.

Many restaurants and businesses use a cool-room to store and age their meat. Cool-rooms actually over-dry the meat as the temperature cannot be controlled efficiently and is often too cold. This leads to the fat of the meat cracking, thick dried out crusts and lower fermentation which means a lot of product is wasted when it is prepared for sale. Importantly, the enzymes are unable to effectively breakdown the muscle tissue, meaning a juicy, melt-in-your-mouth steak is unachievable.

So how does a dry-aging cabinet improve your meat products?

The Dry Ager offers full control of temperature (in precise 0.1°C increments) and humidity (in 0.1% increments between 60-90%) without the need for an external water supply. This takes the guesswork out of producing a quality steak, leading to consistent, high standard results.

The isolating, tinted, lockable glass door ensures the meat is protected from harmful UV rays, while the carefully regulated microclimate by the DX AIRREG system takes care of the meat from the inside. A activated charcoal carbon filter and UVC ventilated disinfectant system sterilizes the air inside the cabinet every minute, instantly obliterating germs or bacteria and ensuring the meat is always 100% safe.

We suggest a temperature of 2°C and a humidity setting of 85% for the most tender, flavoursome beef. The longer the meat is stored, more intense flavours are produced and the softer it becomes.

Preparation is very simple, with multiple beef saddles hung or stored on the bone to do its own work. Adjustable shelves and hangers maximise storage space for added quantity as well as quantity. Once the aging process is complete, the thin crust is trimmed off, de-boned or can be cut into individual steaks for cooking or single serve vacuum packages for sale.

After aging on the bone in the cabinet for 4 weeks, the weight loss of beef is outstandingly small, a maximum of 7-8% as opposed to as much as 30% when dry aged in cool rooms and standard fridges.

In addition to adding value to your business through higher product standards, a dry-aging cabinet can become a focal point of your retail operation. A large, brightly lit fridge full of quality beef evokes a sense of professionalism and excellence, and illustrates the effort and expertise that is ingrained in each product.

We guarantee the amazing flavours that are self-produced by using a dry-aging cabinet will transcend any other beef prep method you currently use or don’t use. The variable cabinet sizes cater to a range of food businesses including restaurants, artisan meat suppliers and even home beef enthusiasts.

The Dry Ager is not only limited to dry aging beef, lamb or pork, but can be used for the production of charcuterie and smallgoods, air drying cured ham, maturing cheese or simply as a good looking fridge.

Dry Aging takes time.

It’s a natural process. It’s worth the wait.

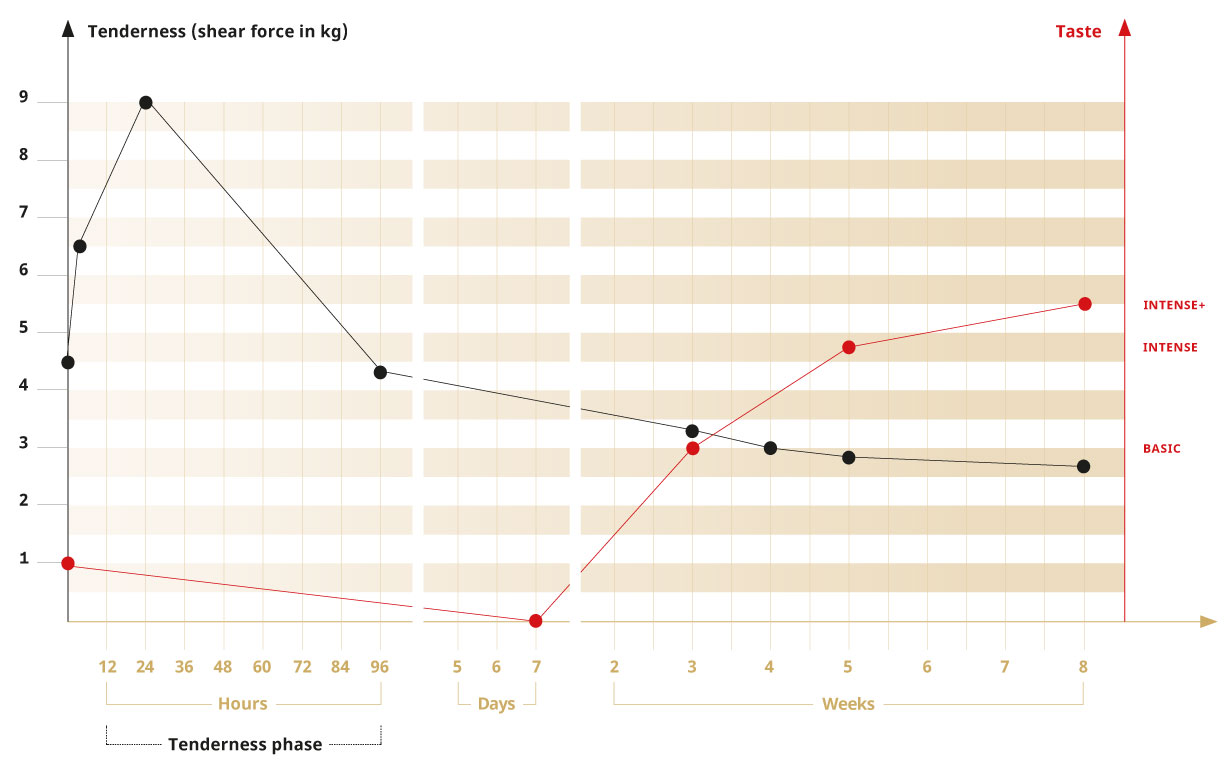

The following diagram shows the changes that occur in the meat (beef, in this example) at different aging times. Both the intensity of flavor as well as the tenderness are strongly dependent on time.

-

The black curve describes the change in tenderness. This is expressed by what’s known shear force. The lower this is, the more tender the meat.

The black curve describes the change in tenderness. This is expressed by what’s known shear force. The lower this is, the more tender the meat.

-

The red curve describes the change in flavor intensity. The higher, the more intense the flavor.

The red curve describes the change in flavor intensity. The higher, the more intense the flavor.